What are traction bars, and why do I need them?

22 December, 2021

If you’ve noticed your rear end hopping around like a kid on a hopper ball, your truck probably suffers from axle wrap. Axle wrap is when the axle rotates in the opposite direction your wheels are spinning, causing suspension components to bind. Axle wrap can lead to premature U-Joint failure or shearing into two pieces like the picture below.

Lift blocks and boosted launches can amplify the effects of axle wrap. For example, lifting your truck increases your driveshaft angle and moves the leaf springs further from the axle. Coupled with boosted launches, you have a recipe for disaster.

Traction bars are the perfect addition to lifted and high horsepower trucks alike. They reduce axle wrap while simultaneously improving rear wheel traction. Traction bars are constructed from DOM tubing or fabricated steel and connect the frame to the rear axle.

Most traction bars are designed specifically for your year, make, and model but can be purchased in a universal kit. In addition, most traction bars designed for your application will include bolt-on brackets, while some will consist of weld-on brackets. Bolt-on versus weld-on is an age-old argument, but it is a personal preference.

High-end traction bars typically include poly joints or johnny joints which allow you to adjust preload or install them exactly where you want them. If you decide to lift or lower your truck in the future, you can adjust the joint rather than move the bracket.

Here are some common reasons as to why you would want traction bars on your truck:

- Your rear end hops while getting on it.

- You want to improve traction while towing.

- You want your rear end to feel planted in the ground.

- You don’t want to replace U-joints as often.

- You are lifting your truck with rear lift blocks.

- You enjoy doing boosted launches or burnouts, especially with a lifted truck.

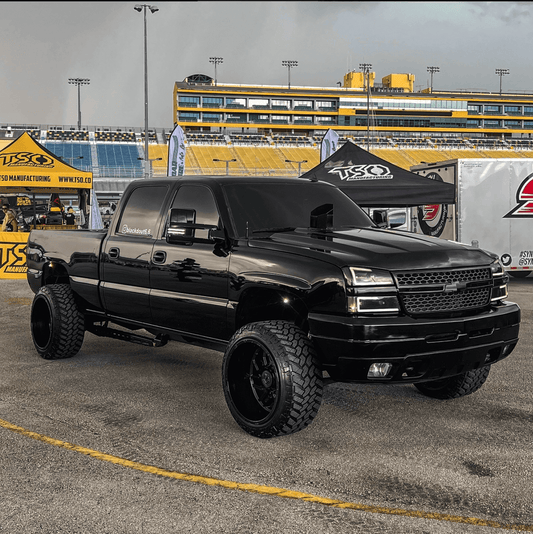

- You drive a show truck and need something to stand out.